Stage I. Design, manufacture, plasma treatment and characterization of textile with electromagnetic and fire retardant properties

Objectives

The objectives of this stage envisage a more modern and ecological approach for obtaining plasma techniques in optimized configurations of textiles coated with metallic films and silicon oxide. It is intended to implement PVD and PECVD systems that allow deposition of adherent and compact thin films under reproducible conditions of the technical processes, onto textile substrates designed and weaved by the consortium, and with technical parameters adapted to the project area of interest (BUILDTECH).

The main results attained during Stage 1 - 2018

This stage was focused on three main directions, namely:

a) To elaborate bibliographic studies that evidence the advantages and the limitations of the various plasma experimental systems that can be used for the depositions of thin films, respectively some studies on the interaction of electromagnetic waves with textiles materials coated with metallic and barrier layers and to evidence the modalities of electromagnetic shielding modeling and evaluation. It has been established that the method of separating variables applied to textile structures with homogeneous planes or grid-type is adequate for the present studies, based on the relationships that link the simplified attenuation factor

to the distance between the grids of the material within the frequency limits

-

fmax < 20 MHz.

b) To elaborate modern deposition experimental systems based on magnetron sputtering of metallic layers and chemical vapor deposition of silicon-containing layers, including the possibility of operation in the same chamber, as shown in Figure 1. The integrated approach of the project included all the steps: from the design of textiles based on 100% BBC natural yarns, synthetic 100% PES yarns, as well as by the inclusion of special yarns containing stainless steel or silver into textiles to provide EM grid structures, to their practical manufacturing in the production facilities of the SME partner, and subsequently exposure to plasma under various deposition conditions.

Yarns characteristics were determined using SR 7271: 2008 and SR 13152: 1993 standards. Depositions experiments of thin metallic and silicon oxide layers have been done, by independently varying 6 experimental parameters, namely the substrate type, the number of coated faces, the Ar flow rate in PVD depositions, the O2 flow rate in PECVD depositions, the RF power, and the deposition time. This approach led to performing of more than 150 samples in this stage of the project.

|

Figure 1. The sketch of deposition chamber and the assembling of PVD/PECVD plasma sources |

c) Morphological, structural and compositional characterization as well as physico-mechanical properties, thermal resistance, and contact angle, respectively, flame retardation and electromagnetic attenuation characteristics.

Plasma coated fabrics with Cu and SiOC / SiOx have improved physical-mechanical and physico-chemical characteristics, increased fabric weights by 8-10% and thickness by 12-16% compared to untreated samples. The scanning electron microscopy images highlight the obtaining of compact, adherent depositions with a texturing tendency at high deposition times, as can be seen in Figure 2. A pronounced hydrophobic character of the treated fabrics was evidenced by the measured contact angle in the range 126 -142 o, and presenting increased endurance upon flame exposure.

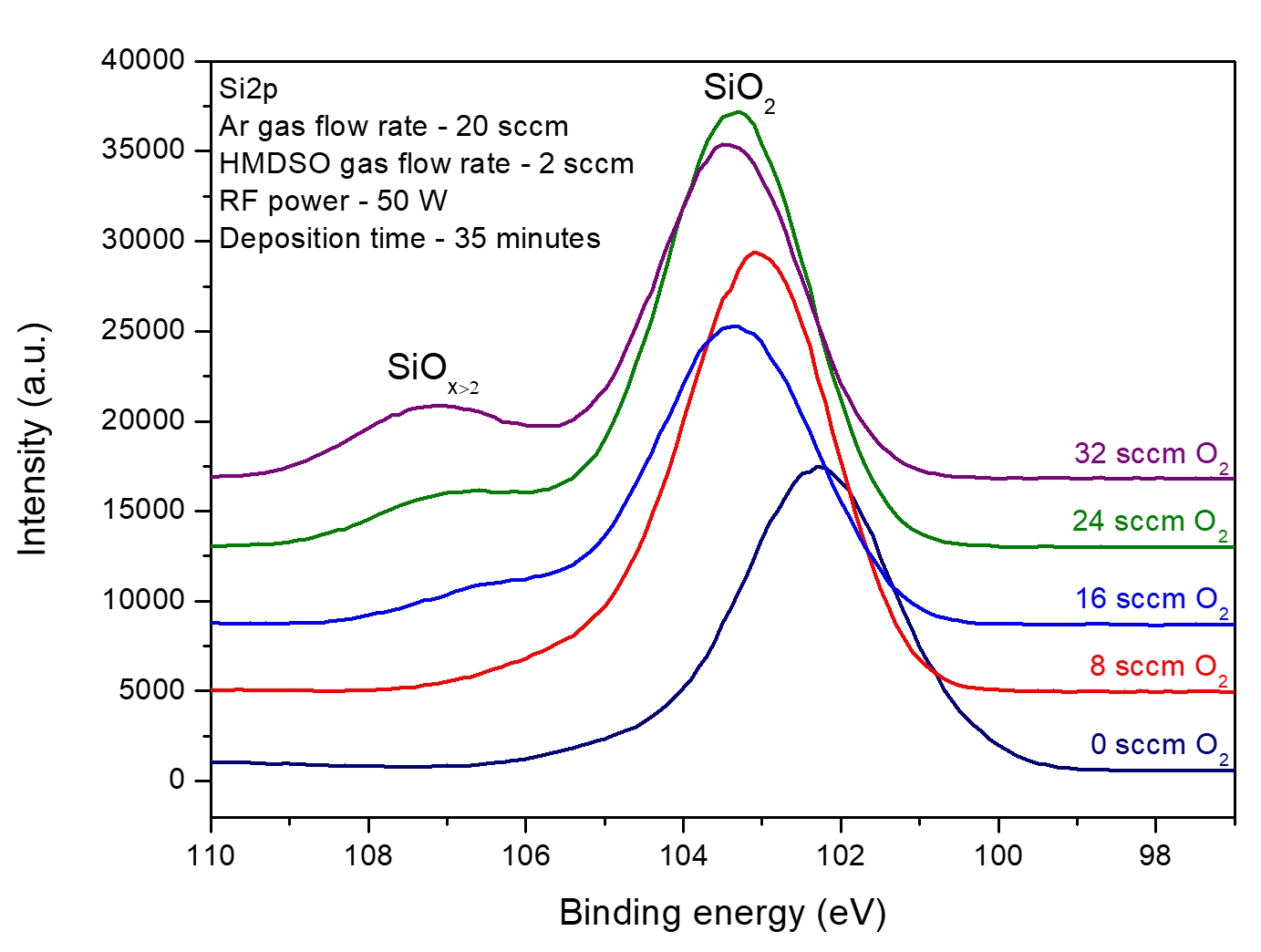

Compositional measurements (Figure 3) demonstrated the possibility of varying the silicon oxide -like thin films composition by modifying the flow of oxygen in the discharge. Samples of flame retardant fabrics obtained by the classical foularding process contain fluorine, phosphorus and silicon and present flame retardant character, and fire retardant polyester fabrics with silicon oxide-like layers have an increased melting point from 257.2 °C to 260.3 °C.

|

Figure 2. a, b) SEM images for textile samples deposited with 1200 nm Cu, c) Water contact angle values depending on the thickness of the Cu layer |

The EM attenuation was analyzed for treated fabrics using the TEM cell based on the ASTM ES-07 standard. Fabrics with conductive silver (TXM94 / 95) and stainless steel (TXM90 / 91) yarns coated in plasma with Cu layers on both sides of the material presented EM attenuation between 20-33 dB. A good correlation between linear conductivity of textiles and EM attenuation could be established. For the single-face treated fabrics, the value of EM attenuation was at a low level of 3-8.5 dB.

|

Figure 3. The evolution of the Si2p spectrum with the discharge oxygen flow (SiOx)

|

The dissemination activity was much more intense than that provisioned in the working plan, and it resulted in 1 ISI paper and 2 BDI indexed papers, as well as the participation at 6 Romanian and international conferences on the project theme.

List of ISI and BDI papers

1. I. R. Rădulescu, L. Surdu, E. Visileanu, M. Costea, I. Patru, V. Voicu, Modelling and testing the electromagnetic near field shielding effectiveness achieved by woven fabrics with conductive yarns, Industria textilă, 69 3/2018, 169-176 (ISI)

2. L. Surdu, E. Visileanu, I.R. Rădulescu, Metode noi de investigare pentru determinarea caracteristicilor materialelor textile funcționalizate, Buletinul AGIR An XXIII nr. 3/2018 (BDI), 42-45

3. I.R. Rădulescu, L. Surdu, E. Visileanu, M. Costea, B. Mitu, Ecranarea câmpului electromagnetic apropiat prin structuri textile țesute, Buletinul AGIR, An XXIII, nr. 3/2018 (BDI) 46-50

List of participations at national and international conferences

1. L. Surdu, E. Visileanu, I.R. Rădulescu, Metode noi de investigare pentru determinarea caracteristicilor materialelor textile funcționalizate, Simpozion PROGRESUL TEHNOLOGIC-REZULTAT AL CERCETARII, editia a XIII-a, București, 26 aprilie 2018

2. I.R. Rădulescu, L. Surdu, E. Visileanu, M. Costea, B. Mitu, Ecranarea câmpului electromagnetic apropiat prin structuri textile țesute, Simpozion PROGRESUL TEHNOLOGIC-REZULTAT AL CERCETARII, editia a XIII-a, București, 26 aprilie 2018

3. S.D. Stoica, V. Satulu, T. Acsente, B. Mitu, G. Dinescu, Monitoring the hydrogenated/fluorinated carbon layers deposition by Optical Emission Spectroscopy, ESCAMPIG XXIV, Glasgow, Scotland, July 17-21, 2018

4. I.R. Rădulescu, L. Surdu, E. Visileanu, Fabric’s testing and modelling for prediction of shielding effectiveness, Conferinta internationala in domeniul textil “VI Scientific – Vocational Conference: Development tendencies in the textile industry- Design, Technology, Management – June 2018, Serbia

5. B. Mitu, V. Satulu, R.I. Radulescu, L. Surdu, G. Dinescu, Plasma deposition of textiles for obtaining electromagnetic shielding and fire-retardant properties, 16th International Conference on Plasma Surface Engineering, September 17 - 21, 2018, Garmisch-Partenkirchen, Germany / poster presentation

6. I.C. Constantin, A.A. Ardeleanu, V. Marascu, C. Stancu, B. Mitu, G. Dinescu, Improvement of Cu magnetron sputtering deposition process for textile fabrics application, The 6th International Colloquium “Physics of materials” (PM 6) 15-16 November 2018 Bucharest, Romania

Manufacturing textiles with electromagnetic shielding and fire retardant properties by plasma based methods

Manufacturing textiles with electromagnetic shielding and fire retardant properties by plasma based methods